Atmospheric Pressure

|

Atmospheric Pressure @ Sea Level

|

Absolute

Pressure

The sum of the available atmospheric pressure and the gage pressure in the

pumping system

Absolute Pressure

(PSIA) = Gauge Pressure + Atmospheric Pressure

|

|

Absolute P. = 150

PSIG (Gauge P.) + 14.7 PSI (Atmospheric P.) = 164.7 PSIA

Vacuum

The full or partial

elimination of Atmospheric Pressure

Atmospheric Pressure

on the Moon = 0 = Full Vacuum

1 Inch Hg Vacuum =

1.13 Ft of Water

Specific

Gravity

Specific Gravity is the ratio of the weight of

anything to the weight of water.

|

|

Specific Gravity of

HCl = (Weight of HCl)/(Weight of Water) = (10.0)/(8.34) = 1.2

Pressure

and Liquid Height Relationship (Head)

|

|

1 PSI = 2.31 Ft of

Water

Pressure, Liquid

Height, & Specific Gravity Relationship

|

|

Pressure (PSI) = Head (FT) x Specific Gravity (SG) / 2.31

Example - Water -

231Ft x 1.0 / 2.31 = 100 PSI

Example - HCL - 231

Ft x 1.2 / 2.31 = 120 PSI

Example - Gas - 231

Ft x .80 / 2.31 = 80 PSI

Vapor

Pressure

|

|

The pressure pushing

against atmospheric pressure on liquids at elevated temperatures.

Suction

Head

|

|

A Suction Head

exists when the liquid is taken from an open to atmosphere tank where the

liquid level is above the centerline of the pump suction, commonly known as a

Flooded Suction.

Total

Dynamic Head

Total Dynamic Head

(TDH) = Elevation(ft) + Friction(ft)

|

|

Centrifugal

Pump Components

The two main

components of a centrifugal pump are the impeller and the volute. The impeller

produces liquid velocity and the volute forces the liquid to discharge from the

pump converting velocity to pressure. This is accomplished by offsetting the

impeller in the volute and by maintaining a close clearance between the

impeller and the volute at the cut-water. Please note the impeller rotation. A

centrifugal pump impeller slings the liquid

out of the volute. It does not cup the

liquid.

|

|

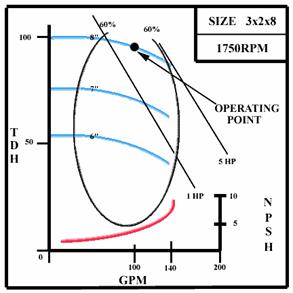

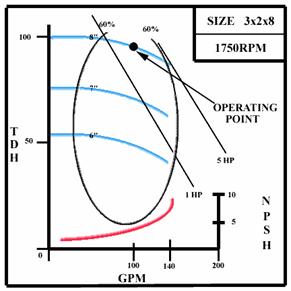

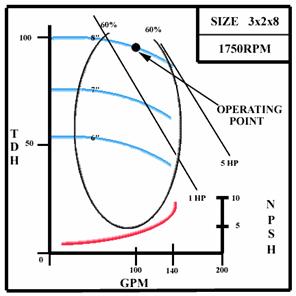

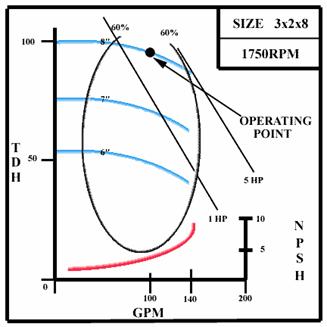

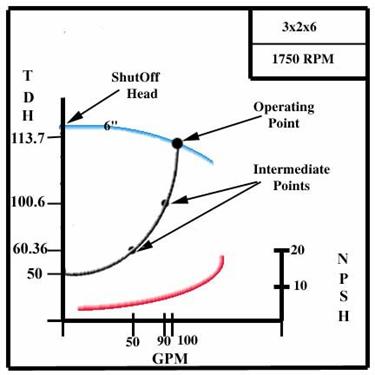

Pump

Performance Curve

A Pump Performance

Curve is produced by a pump manufacturer from actual tests performed and shows

the relationship between Flow and Total Dynamic Head, the Efficiency, the NPSH

Required, and the BHP Required.

Higher Head = Lower

Flow Lower Head = Higher

Flow

Lower Flow = Lower

Horsepower Higher Flow =

Higher Horsepower

|

|

Based on Water SG

1.0

Capacity

A Centrifugal Pump

is a variable displacement pump. The actual flow rate achieved is directly

dependent on the Total Dynamic Head it must work against.

The flow capacity of

a centrifugal pump also depends on three (3) other factors:

1

Pump Design

2

Impeller Diameter

3

Pump Speed

|

|

Affinity Laws

The performance of a

centrifugal pump is affected by a change in speed or impeller diameter.

|

|

Q = Capacity (GPM) D = Impeller Diameter N= Speed(RPM)

H = Total Dynamic

Head(Feet) BHP

= Brake Horsepower

The affinity law for

a centrifugal pump with the impeller diameter held constant and the speed

changed:

Flow: Q1 / Q2 = N1 / N2

Example: 100 / Q2 = 1750/3500 Q2 = 200 GPM

Head: H1/H2 = (N1) x (N1) / (N2) x (N2)

Example: 100 /H2 = 1750 x 1750 / 3500 x 3500 H2 = 400 Ft

Horsepower (BHP):

BHP1 / BHP2 = (N1) x

(N1) x (N1) / (N2) x (N2) x (N2)

Example: 5/BHP2 = 1750 x 1750 x 1750 / 3500 x 3500 x

3500 BHP2 = 40

The affinity law for

a centrifugal pump with the speed held constant and the impeller diameter changed:

Flow: Q1 / Q2 = D1 / D2

Example: 100 / Q2 =

8/6 Q2 = 75 GPM

Head: H1/H2 = (D1) x (D1) / (D2) x (D2)

Example: 100 /H2 = 8

x 8 / 6 x 6 H2 = 56.25 Ft

Horsepower (BHP):

BHP1 / BHP2 = (D1) x

(D1) x (D1) / (D2) x (D2) x (D2)

Example: 5/BHP2 = 8

x 8 x 8 / 6 x 6 x 6 BHP2 = 2.1

Brake

Horsepower

BHP = Flow(GPM) X

TDH(FT) x SG /3960xEFFICIENCY(%)

Example: BHP = (100

GPM) x (95 Ft) x (1.0) / 3960 x .6 BHP

= 4.0

|

|

Calculating

Total Dynamic Head (TDH)

Flooded Suction

Application

|

|

TDH = Total

Discharge Head - Total Suction Head

Total Suction Head =

Static - Friction

Total Discharge Head

= Static + Friction

Suction Lift

Application

|

|

TDH = Total

Discharge Head + Total Suction Lift

Total Suction Lift=

Static + Friction

Total Discharge Head

= Static + Friction

Total Dynamic Head =

Total Discharge Head + Total Suction Head

System

Head Curve

To Calculate a

System Head Curve several points must be chosen to calculate friction losses on

both the suction and discharge sides of the pump at various flow rates. The

static suction head/lift and the static discharge head remain constant.

|

|

Net

Positive Suction Head

Net Positive Suction

Head Required (NPSHR)

The net positive

suction head required is a function of the pump design at the operating point

on the pump performance curve.

Net Positive Suction

Head Available (NPSHA)

The net positive

suction head available is a function of the pump suction system.

The Net Positive

Suction Head is the absolute total suction head in feet.

The NPSH available

in a flooded suction system is:

|

|

Atmospheric Pressure (-) Vapor

Pressure (+) Liquid Height (-) Friction in the Suction Line.

The NPSH available

in a suction lift system is:

Atmospheric Pressure

(-) Vapor Pressure (-) Liquid Ht. (-) Friction in the Suction Line.

|

|

If

the NPSHA < NPSHR the Pump will cavitate

Cavitation

Cavitation may occur

in two different forms:

Suction Cavitation

Suction Cavitation

occurs when the pump suction is under a low pressure/high vacuum condition

where the liquid turns into a vapor at the eye of the pump impeller. This vapor

is carried over to the discharge side of the pump where it no longer sees

vacuum and is compressed back into a liquid by the discharge pressure. This

imploding action occurs violently and attacks the face of the impeller. An

impeller that has been operating under a suction cavitation condition has large

chunks of material removed from its face causing premature failure of the pump.

Discharge Cavitation

Discharge Cavitation

occurs when the pump discharge is extremely high. It normally occurs in a pump

that is running at less than 10% of its best efficiency point. The high

discharge pressure causes the majority of the fluid to circulate inside the

pump instead of being allowed to flow out the discharge. As the liquid flows

around the impeller it must pass through the small clearance between the impeller

and the pump cutwater at extremely high velocity. This velocity causes a vacuum

to develop at the cutwater similar to what occurs in a venturi and turns the

liquid into a vapor. A pump that has been operating under these conditions

shows premature wear of the impeller vane tips and the pump cutwater. In

addition due to the high pressure condition premature failure of the pump

mechanical seal and bearings can be expected and under extreme conditions will

break the impeller shaft.

|

|

Suction

Cavitation & Discharge Cavitation are extremely damaging to pump

components.